Gas-To-Liquid Technology

Home > Industries > GTL Technology

Providing Waste Gas Solutions

Gas flaring, the process of burning-off associated gas from oil wells and hydrocarbon processing plants either as a means of disposal or as a safety measure, is today recognized as a major environmental problem, contributing millions of tons of Methane and CO2 emissions worldwide. It also has major economic implications, with significant volumes of a valuable natural resource being wasted. Today, ENG offers clients worldwide a cost-effective solution.

As an EPC and fabricator for more than 37 years, ENG’s Gas to Liquids (GTL) technology enables industry to valorize and monetize waste gases and meet new emissions standards to achieve zero routine flaring and venting targets set out by COP27 for 2030.

GTL Technology

ENG’s GTL technology is proven, modular and scalable. It operates at very low power levels, can accept various gas feed compositions directly from the well pad, flare line, or processing unit.

Our GTL plants can be designed for on & offshore mid-scale applications to convert associated, stranded, bio, landfill, and coal methane gas into valuable Synthetic liquids such as Syncrude, diesel blend, methanol, and paraffins.

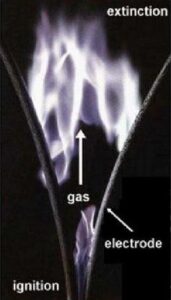

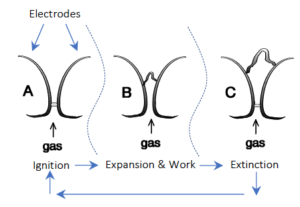

Our GTL process combines two highly advanced processes. The first being a non-thermal gliding arch plasma reformer to produce syngas. The reformer utilizes the gliding arc to create radicals, ions, and excited states (translational, vibrational, and electronic) within the vaporized feed stream to promote breaking of chemical bonds for reforming aromatics and hydrocarbons into Syngas.

The second process improves the traditional Fischer-Tropsch reactor by using 4” reactor tubes with a proprietary reactor tube insert extrusion that provides improved temperature control throughout the reactor length.

Aside from the technical advantages, ENG inhouse manufacturing capabilities allows us to design and build our GTL plants in-house. They are modularized to simplify transportation and installation and can handle a wide range of site conditions.

ENG Technology Benefits

- ENG GTL plants are easily truck transportable and can be quickly moved to another site.

- Demobilization and Mobilization in as little as 48 hours.

- GTL plants are designed and built to remain in place for 25 years.

- Achieve Zero Routine Flaring.

- Achieve and surpass corporate and legislative ESG targets.

- Significantly reduce GHG emissions.

- Designed, manufactured, and tested using in accordance with ISO 9001 QMS standards.

- Class 1 Division 2 electrical standards, fail closed isolation and auto shutdown.

- Proven record of safety.

- Designed for all environments, from -40F to +120F.

- Designed for 25 year field life.

- Inhouse design and built proprietary automation control and remote monitoring.

- Can achieve an uptime over 98%.

- Scalable GTL trains to meet current and future feed gas volumes.

- Significant turndown capabilities for flexible capacity.

- GTL trains can start from 250Mscfd to 20MMscfd.

- Can be trailer-mounted for systems field testing with larger systems purpose-built for long-term operations.

- Monetization of waste gas to produce high value added products.

- Creating In Country Value (ICV).

- Replace diesel and other fuel costs at lesser landed costs.

- Rapid ROI on equipment and development investment.

- No feed gas pre-treatment or separation

- ENG to manage gas feed conditions

Revenue Streams

- 100% conversion of flare, vented or flare gas into diesel blend, gasoline and waxes.

- Utilization of current personnel to mange production.

- No need for additional logistics.

- Can be blended with oil field crude production.

- Tail Gas can be used to produce power.

- Fuels can be sold to neighboring oil field operations.

Our Industries

Automation

Automation

Combining more than 30 years of automation expertise and broad industry experience, our automation integration team delivers a complete suite of fully integrated, process, power and control solutions for a complete range of applications.

Learn More >>Government Services

Government Services

Over 30 years supporting the U.S. Department of Defense (DOD) fueling systems with engineering and automation solutions.

Learn More >>Process, Power & Controls

Process, Power & Controls

ENG provides total project responsibility, from Front-End Engineering and Design (FEED), Detailed Design, and Integration, through commissioning, start-up, and ongoing maintenance.

Learn More >>Oil/Gas & Petrochemicals

Oil/Gas & Petrochemicals

Reliable services, answering the complex challenges faced by energy operatives.

Cost effective, innovative and efficient.

Refinery & Terminals

Refinery & Terminals

Center of expertise in conceptual engineering and designing services for petroleum refining and petrochemical industry.

Learn More >>Energy & Renewables

Energy & Renewables

Technology-driven company providing a complete turnkey solution for alternative and sustainable energy engineering projects.

Learn More >>Need more information?

Our Services

Project

Management

Project

Management

Supporting the project from conception to completion, our integrated management teams work collaboratively to provide the solutions that are right for your project.

Learn More >>Engineering

Engineering

Our engineering, design and fabrication group delivers multi-disciplined and complete services with a focus on process performance, constructability and operational safety.

Learn More >>Procurement

Procurement

Our efficient procurement process reduces financial risk and improves decision making through the whole project life cycle.

Learn More >>Integration

Integration

Design and fabrication of process modular systems that are ready for production upon delivery to greenfield and brownfield locations.

Learn More >>Fabrication

Fabrication

We proudly design, build, and test in-house tailored fabrication solutions that are ready for production upon delivery to greenfield and brownfield locations.

Learn More >>